Quality Control

Zero-Defect Commitment – Rigorous Quality Assurance for Precast Accessories Safety

AOP Precast prioritizes safety with comprehensive quality control for forged, stamped, and welded accessories, ensuring reliability for US precast factories and distributors over 20 years.

Certified Quality Management Systems

ISO 9001:2015

Global standard for quality management, focusing on consistency and improvement.

US-Specific Certifications

ASTM, CE, and safety compliance for US market requirements.

We use APQP, FMEA, PPAP, and SPC tools to meet client specs and safety needs.

End-to-End Quality Control Process

1. Incoming Material Inspection

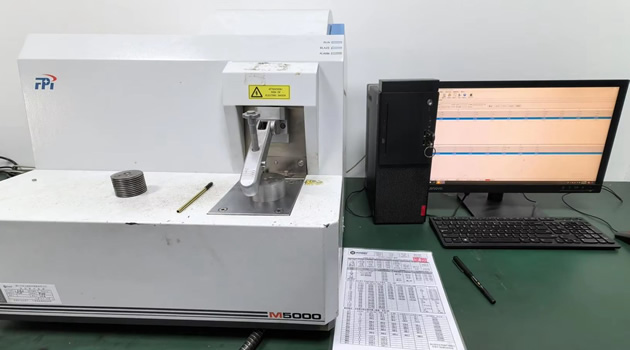

Spectrum Analyzer for steel alloys chemical, ensuring high-strength and corrosion resistance.

2. In-Process Monitoring

SPC for forging/stamping/Tapping parameters, preventing defects.

3. Post-Production Inspection

Load testing, hardness checks, visual inspections for safety.

4. Final Verification

PPAP documentation and traceability for US clients.

Advanced Inspection & Testing Methods

Load & Strength Testing

2-5 times rated load tests for safety compliance.

Hardness & Material Analysis

Rockwell testing and spectrometer for alloy integrity.

SPC & Dimensional Checks

Statistical control for tolerances and variation.

Non-Destructive Testing

Ultrasonic and visual inspections for weld quality.

Corrosion & Finish Inspection

Salt spray tests for galvanizing durability.

Client-Specific Verification

Custom tests based on US distributor specs.

Special Focus: Safety & Defect Prevention

We prioritize safety with strict defect prevention, ensuring accessories withstand extreme loads and environments.

- Acceptance Criteria: Zero defects in critical areas, per client specs.

- Detection: 100% inspection for strength and integrity.

- Prevention: DFM, simulation, and process controls.

Trust in Proven Quality

Our quality system ensures every accessory meets your safety and spec requirements.

Request PPAP Sample or Quality Audit Explore Our Capabilities